Because of their durability, temperature resistance, and ability to withstand high mechanical stresses, malleable iron pipe fittings are popular in the plumbing and pipework industries. Standard jointing technology allows these types of fittings to be used safely in a wide range of applications once galvanized.

Malleable iron pipe fittings offer shock and corrosion resistance as well as mechanical strength. Water can be transported using galvanized fittings galvanized with pure zinc. Because narrow threads seal pipes more tightly, they reduce leakage risk.

At present, Jianzhi Group's malleable pipe fittings are divided into three series according to their product design standards: heavy banded, medium beaded, and beaded. It can also be divided into three different types of pipe fittings based on the galvanizing method: hot-dip galvanizing, electro-galvanizing, and black products. Therefore, we can provide customers with 9 different choices for the same type of product.

l Heavy banded products: products that fully comply with the China national standard GB/T 3287-2011. The working temperature of the product is 200 degrees Celsius, and the working pressure is 1.6Mpa. Tensile strength>330Mpa, elongation>8%, hardness <150HB.

l Medium beaded products: products that meet the standards of construction and support enterprises. Its working strength standard fully meets the national standard, but in order to save costs, it is made smaller in size and thinner in wall thickness. During the production process of malleable, it is difficult to make the product thinner while maintaining the use standard. It is prone to through-hole phenomenon, and its strength and plasticity are also difficult to guarantee. Under the premise of ensuring the quality of products, medium beaded products have successfully reduced product costs and provided customers with more competitive price options.

l Beaded products: In order to meet the price demand of lower-end customers, Jianzhi Group has developed a series of beaded products. Heavy banded products can fully meet the strength requirements of the national standard, as can beaded products. Furthermore, mold release is easy due to the minimal changes in the design and filling capacity of the beaded products, resulting in even lower manufacturing costs.

l Hot-dip galvanizing: After the zinc ingot is dissolved by heating, a layer of zinc film is attached to the surface of the product through the hot-dip process. Through the isolation of the zinc layer, the product is protected from oxidation and rust is prevented. The advantage is that the coating is thick, the thickness of the inner and outer walls is uniform.

l Cold galvanizing: The product is passed through the electrolytic zinc solution, and the zinc ions are attached to the surface of the product under the action of the electrode to form a coating. The advantages are that the coating is uniform, the surface is smooth and beautiful, and the cost is low. The disadvantage is that the thickness of the coating is thin, and the coating on the inner surface is thin due to the magnetic effect of the electrodes. The product can be used in oil systems with low requirements for anti-oxidative corrosion.

l Non-galvanized black pipe fittings: This type of pipe fitting is malleable and does not require galvanizing, and the other steps are the same as the two above.

Pipe bushings are used to join pipes of different sizes - usually by reducing a larger pipe fitting down to a smaller pipe. Bushings are usually threaded inside and outside. They take up very little space compared to a coupling or union, which serve to achieve the same goal of reducing down sizes. Has a hexagonal head for increased leverage and use with a wrench.

Threaded or socket weld pipe elbows are commonly used if you need to change the direction of flow. Most popular: 90 & 45 degree angles elbows. Elbows are a critical fitting used in plumbing. Street elbows feature male and female threaded ends to easily connect differing pipes or fittings. Side outlet elbows featuring a bend serve similar to a tee. 22-1/2 degree elbows are also available.

Caps are availabe in stainless steel 304 or 316 cast pipe fitting with female National Pipe Taper (NPT) threads. For closing the end of a male pipe. The cap fits over the end of a male pipe to stop flow. They are availble also with hex and square heads for increased leverage and use with a wrench during installation and disassembly.

Cross pipe fittings are 4-way fittings that are essentially just the combination of two tees. Many will opt to use two tees instead.

Flanges are used to connect pipes. The pipe is threaded or welded to the flanges which are then sealed together with bolts. Flanged connections are used extensively in industrial applications handling high pressures.

Pipe couplings are used to lengthen the run of a pipe or change pipe sizes.

When reducing this becomes known as a bell reducer. Available with female threads or socket weld.

A pipe nipple is a short stub of pipe which has a male pipe thread at one or both ends. It used for connecting two other fittings. Nipples are used for connecting pipe, hoses, and valves. Pipe nipples are used in low-pressure pipe systems.

Pipe Tees are T-shaped with two outlets - at 90° to the connection to the main line. It is a short piece of pipe with a lateral outlet. Pipe tees are used to connect pipelines with a pipe at a right angle with the line. Tees are sized according to their run*. When the run of a tee is smaller than the side outlet*, it becomes a "bull head" fitting.

Unions are an alternative to couplings. Unions rely upon their own nut to create a seal between the pipe ends. This makes them the perfect choice for connecting two fixed pipes that are unable to be threaded into a regular coupling. Unions also make future repairs that much easier.

Valves are designed to control flow pressures and rates.

Products Category

Products

In malleable cast iron grades, the minimum tensile strength (MPa) and minimum elongation after fracture are expressed as percentages. KTH 350—10, for example, is a ferritic malleable cast iron grade with a minimum tensile strength of 350 MPa and a minimum elongation after fracture of 10%; KTZ 650—02 has a minimum tensile strength of 650 MPa and a minimum elongation after fracture of 650 MPa. Pearlitic malleable iron with a rate of 2%.

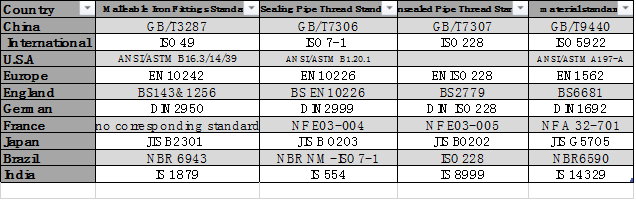

According to China's national standard, malleable iron pipe fittings must comply with GB/T3287-2011, and malleable iron materials must comply with GB/T9440-2010. These two standards are drafted primarily by Jianzhi Group, which plays an important role in revisions. KTH300-06, KTH330-08, and KTH350-10 are among the grades of black-heart malleable cast iron.

The material used by Jianzhi Group is KTH-330-08. KTH300-06 meets the national standard with a 10% higher tensile strength and 33% higher elongation than KTH300-06.

Water supply and drainage pipeline systems have high requirements for anti-rust properties; therefore, galvanized pipe fittings are generally used. In particular, hot-dip galvanized pipe fittings have thicker galvanized layers, stronger rust resistance, and more corrosion resistance. It is not only in the field of water supply and drainage that hot-dip galvanized pipe fittings should be used in corrosion-prone applications. In the case of heavy-banded, medium-beaded, and beaded, your budget and local national codes or local building codes should be taken into account. However, if you have more stringent safety requirements, you should consider a higher standard fitting.

In the oil system, because the oil itself has the effect of preventing the rust of the pipe fittings, non-galvanized pipe fittings are generally selected. It is difficult for the inner wall of the pipe to rust when the pipe is transporting oil. This is because it is in contact with oil, but the outer surface still has the possibility of rusting and aging. Spray paint treatment enhances the corrosion resistance of the outer surface of pipe fittings. Furthermore, because non-galvanized black pipe fittings show the natural beauty of cast iron and have a distinctive texture, black pipe fittings are used for handicrafts. They can also be sprayed with different colors of paint on their surfaces to make all kinds of beautiful handicrafts.

Gas transmission is an increasingly popular application field for malleable pipe fittings. Due to the corrosive nature of natural gas, galvanized pipe fittings are selected without exception for malleable pipe fittings that transport natural gas. Moreover, the safety requirements for natural gas pipelines are very high, so the selection of pipe fittings will require the highest standards, that is, heavily banded pipe fittings. Here I would like to remind you that the selection of pipe fittings must be combined with the specific application field. Improper selection may cause serious safety problems. In fields with high safety requirements, high-standard pipe fittings must be selected.

Malleable pipe fittings used in gas systems are extremely safe because of the catastrophic consequences in the event of a leak. The malleable pipe fittings are produced by Jianzhi Group. Each pipe fitting will undergo a pressure test before leaving the factory. Only the pipe fittings that pass the test can be sold. In addition, Jianzhi Group also has the highest quality commitment in the industry. If you find a gray product produced by Jianzhi Group on the market, you will receive a reward of 1,618 RMB from Jianzhi Group. Therefore, there is absolutely no need to worry about quality problems when choosing the malleable pipe fittings of Jianzhi Group.

Each malleable pipe fitting is subjected to a pressure test

After 40 years of development, Jianzhi Group has become the largest manufacturer of malleable pipe fittings in China. We have two super-large malleable pipe fittings manufacturing plants in Tangshan City, Hebei Province, China and Chifeng City, Inner Mongolia, which can meet the annual production capacity of 40,000 tons.

Related Information

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 18698027872

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania

Service email: info.ro@jianzhi-fitting.com

Sales email: market.ro@jianzhi-fitting.com

Tel: +40(755)011 849