Oct. 24, 2022

It is obtained by tempering white iron at high temperature and is often used to make pipe parts, such as various pipe joints. The main applications of malleable iron fittings include heating systems, fire protection systems, etc. The existence of malleable pipe fittings has certain advantages, for example, its mechanical properties are relatively good, and it has high toughness. In terms of strength, hardness and wear resistance, it has good performance, so malleable pipe fittings have a wide range of applications, and it is also a promising building material.

The malleable pipe fittings are connected with the pipeline by thread to ensure good contact and connection with the pipeline. The pressure bearing capacity of this kind of pipe fittings does not exceed 1.6MP. Do not use it under particularly high pressure to prevent some abnormal events. The malleable pipe fittings and pipes are connected together by standardized threads, which saves time and effort in the construction process, and also saves a lot of labor and costs.

Before introducing the specific application fields of malleable pipe fittings, it is necessary for us to give a brief introduction to the types of malleable pipe fittings produced by Jianzhi Group. Only by understanding the most basic knowledge about the types of pipe fittings can we more clearly understand why different fields use different types of malleable pipe fittings.

At present, Jianzhi Group's galvanized malleable fittings are divided into three series according to their product design standards: heavy banded, medium beaded, and beaded. According to the different galvanizing methods, it can also be divided into three different types of pipe fittings: hot-dip galvanizing, electro-galvanizing, and black products. Therefore, we can provide customers with 9 different choices for the same type of product.

Get different information about malleable iron pipe

Products that fully comply with the China national standard GB/T 3287-2011. The working temperature of the product is 200 degrees Celsius, and the working pressure is 1.6Mpa. Tensile strength>330Mpa, elongation>8%, hardness <150HB.

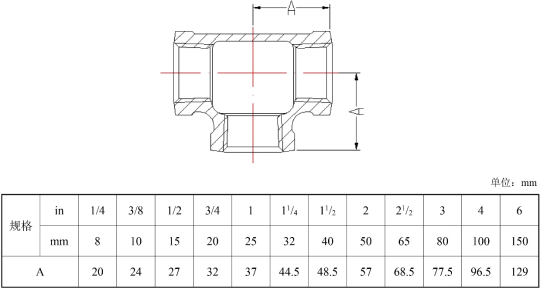

Heavy banded products specifications

Products that meet the standards of construction and support enterprises. Its working strength standard fully meets the national standard, but in order to save costs, it is made smaller in size and thinner in wall thickness. In the production process of malleable, it is very difficult to make the product thinner under the condition of ensuring the use standard. It is prone to through-hole phenomenon, and its strength and plasticity are also difficult to guarantee. Under the premise of ensuring the use of standard products, medium beaded products have successfully reduced product costs and provided customers with more competitive price options.

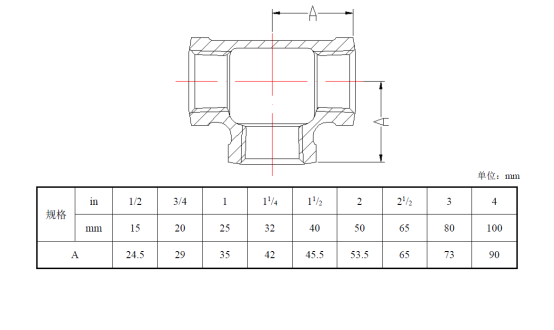

Medium beaded products specifications

In order to meet the price demand of lower-end customers, Jianzhi Group has developed a series of beaded products. Like the Heavy banded products, the beaded products can fully meet the use strength required by the national standard. At the same time, due to the low requirements of the mold design and filling capacity of the beaded products, the mold release is easy, which further reduces its manufacturing cost.

After the zinc ingot is dissolved by heating, a layer of zinc film is attached to the surface of the product through the hot-dip process. Through the isolation of the zinc layer, the product is protected from oxidation and rust is prevented. The advantage is that the coating is thick, the thickness of the inner and outer walls is uniform.

Hot dip galvanized pipe fittings

The product is passed through the electrolytic zinc solution, and the zinc ions are attached to the surface of the product under the action of the electrode to form a coating. The advantages are that the coating is uniform, the surface is smooth and beautiful, and the cost is low. The disadvantage is that the thickness of the coating is thin, and the coating on the inner surface is thin due to the magnetic effect of the electrodes. The product can be used in oil systems with low requirements for anti-oxidative corrosion.

It is difficult to distinguish the difference between hot-dip galvanizing and cold-dip galvanizing in appearance. You can use a professional instrument to measure the thickness of the zinc layer, or use a magnifying glass to view the surface texture to distinguish.

This kind of pipe fitting is a malleable iron fitting without galvanizing process, and other processing steps are the same as the above two.

In the pipeline system of water supply and drainage, there are high requirements for the anti-rust ability of the pipeline, so galvanized pipe fittings are generally selected. In particular, hot-dip galvanized pipe fittings have thicker galvanized layers, stronger rust resistance and more corrosion resistance. In fact, not only in the field of water supply and drainage, hot-dip galvanized pipe fittings should be used in any use environment that requires high anti-corrosion ability. Regarding the choice of heavy banded, medium beaded, and beaded, you should consider your budget and local national standards or building standards for comprehensive consideration, but if you have higher requirements for safety in use, it is recommended that you purchase higher Standard fittings.

In the oil system, because the oil itself has the effect of preventing the rust of the pipe fittings, non-galvanized pipe fittings are generally selected. But there is a problem that when the pipe is transporting oil, it is difficult for the inner wall of the pipe to rust because it is in contact with the oil, but the key outer wall still has the possibility of rusting and aging. Spray paint treatment to enhance the corrosion resistance of the outer surface of the pipe fittings. In addition, because the non-galvanized black pipe fittings directly expose the metal primary color of malleable cast iron and shine with a unique metallic texture, many black pipe fittings are used to make handicrafts. On the one hand, the color and texture of the black pipe fittings are very beautiful, and on the other hand, they can also be sprayed with different colors of paint on their surfaces to make all kinds of beautiful handicrafts.

Gas transmission is an important application field of malleable iron fittings. Due to the corrosive nature of natural gas, galvanized pipe fittings are selected without exception for the malleable pipe fittings that transport natural gas. Moreover, the safety requirements of natural gas pipelines are very high, so the selection of pipe fittings will require the highest standards, that is, heavy banded pipe fittings. Here I would like to remind you that the selection of pipe fittings must be combined with the specific application field. Improper selection may cause serious safety problems. In fields with high safety requirements, high-standard pipe fittings must be selected.

pipe fittings for gas delivery system

Of course, there are many application fields of pipe fittings, and it is difficult to list them all. I hope the explanation in this article will help you.

Here, it is recommended that you pay attention to the malleable pipe fittings produced by Jianzhi Group. Jianzhi Group is a professional manufacturer of malleable pipe fittings in China. And the annual production capacity reaches more than 400,000 tons, with absolutely sufficient supply capacity. The three series of malleable pipe fittings and different galvanizing methods mentioned in this article are combined with a total of 9 types of products. Jianzhi Group can provide them. Welcome to pay attention.

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 18698027872

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania

Service email: info.ro@jianzhi-fitting.com

Sales email: market.ro@jianzhi-fitting.com

Tel: +40(755)011 849