Dec. 08, 2022

In daily life, people often make analogies to some phenomena, and thus misunderstand some things that meet the standards. Recently, our business team has often fed back such a problem: customers always think that the threads of malleable pipe fittings of Jianzhi Group have quality problems.

The reason is that the threads of the malleable pipe fittings of Jianzhi Group cannot be completely screwed in, and a lot of them are always exposed as shown in the figure below.

It is true that the thread is tightened when it is exposed so much, which does not conform to the general perception of many people. In the general imagination of many people, the thread of the malleable pipe fittings should be like the water bottle in the picture below, and it is the best and the tightest to be completely screwed in.

But for malleable pipe fittings, this understanding is wrong. What is wrong with it, let's explain it below.

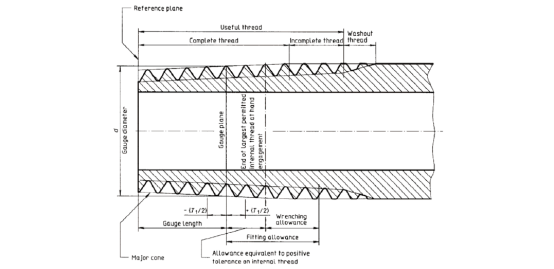

First, take the British standard thread EN10242 commonly used by Jianzhi Group as an example. The British standard thread is a 55-degree sealed tapered pipe thread belonging to the Whitworth thread family. It is mostly used in Europe and Commonwealth countries and is often used in the water and gas pipe industry. The taper is 1:16.

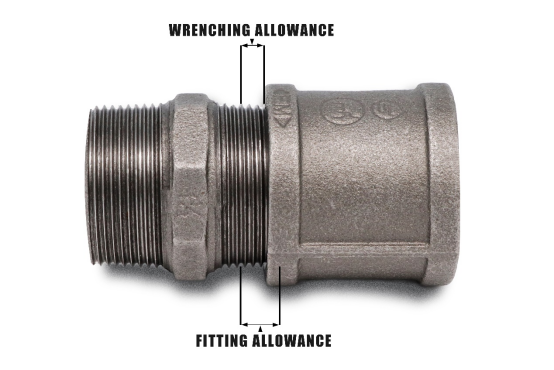

From the example in the above figure, we must pay attention to a key parameter, namely the Wrenching allowance. The Wrenching allowance is the remaining effective thread length after the inner and outer tapered threads are hand-tightened. To put it simply, the threads will be assembled and tightened by hand first, and then further tightened with tools to completely seal the pipe fittings. At this time, it is necessary to leave a tightening margin for the threads to further tighten the threads with tools. Can be achieved. In addition, as shown in the figure above, related to the Wrenching allowance, there is also a concept of Fitting allowance.

Fitting allowance = Wrenching allowance + internal thread reference plane position tolerance / 2

Therefore, when the tolerance is small enough, the Wrenching allowance can even be equal to the Fitting allowance.

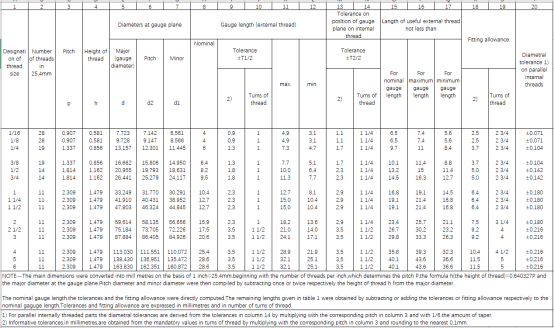

The figure below shows some parameter requirements corresponding to threads of different diameters under the British standard.

As shown in the figure above, in the column of Fitting allowance, the number of Fitting allowance threads corresponding to pipe threads of different sizes is displayed. For pipe threads of a size less than or equal to 1 1/2, the number of Fitting allowance turns is 2 3/4 Turns, pipe threads larger than 1 1/2 size, the number of turns of the Fitting allowance will increase accordingly.

Taking the 1 1/2 size black malleable pipe fittings of Jianzhi Group as an example, the nipple and pipe joint in the above picture are already in the hand-tightened state

, the exposed threads at this time just meet the thread Fitting allowance requirements. In addition, please note that the Fitting allowance of the thread does not refer to all exposed threads, but to the effective threads. Because in the process of tapered thread processing, incomplete threads are inevitably formed at the end of the thread, and this part of the incomplete thread cannot be counted as an effective thread. For the thread of 1 1/2 size black malleable pipe fittings, we can perform a simple calculation according to the British standard to find out how many threads are qualified in the state of hand screwing in:

Size: 1 1/2

Tolerance: 1 turn

Incomplete thread: 2 turns

Tightening allowance: 2 3/4 turns

Exposed thread=2 3/4+2±1= 4 3/4±1 turns

Therefore, for pipe threads with a size of 1 1/2, the number of turns of the exposed thread between 3 3/4 turns and 5 3/4 turns is in line with the standard. Simply put, the exposed threads are between 3 turns and 5 turns are all in line with the standard.

Of course, this is only the value calculated for 1 1/2 size malleable pipe fittings. Different sizes will also calculate different values. You may wish to calculate according to the standard table to see if the malleable pipe fittings you purchased meet the corresponding standards.

Through the above analysis, we can confirm that the malleable pipe fittings products of Jianzhi Group absolutely meet the standards. In fact, the key to researching this issue is that when we face products in some professional fields, we try not to use simple life experience to judge whether they are qualified and meet the quality standards. In fact, in every field, especially in the field of professional hardware and building materials, because of safety issues, quality standards are undoubtedly the most concerned by people, so the quality standards in this field are also the most complete and strict. When encountering the above problems, please be sure to learn and understand the relevant quality standards before making a judgment, instead of relying on the inertia of thinking in life to give a wrong understanding.

The malleable pipe fittings products of Jianzhi Group have always been produced in strict accordance with relevant standards, even stricter than some standards. Therefore, if you choose Jianzhi Group, you absolutely don’t have to worry about quality issues. Jianzhi Group has been focusing on the full-process production of malleable pipe fittings.

For more information on Jianzhi Group malleable pipe fittings, follow us at malleableiron-pipefitting.com

and inspire your interest in the future of solar roofing at

Youtube: @Hebei Jianzhi Casting Group Co., Ltd.

Facebook: @Hebei Jianzhi Casting Group Co., Ltd.

Linkedin: https://www.linkedin.com/company/ironpipefittings

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 18698027872

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania

Service email: info.ro@jianzhi-fitting.com

Sales email: market.ro@jianzhi-fitting.com

Tel: +40(755)011 849