Nov. 09, 2022

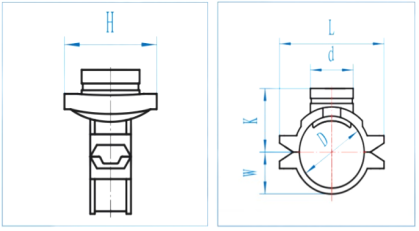

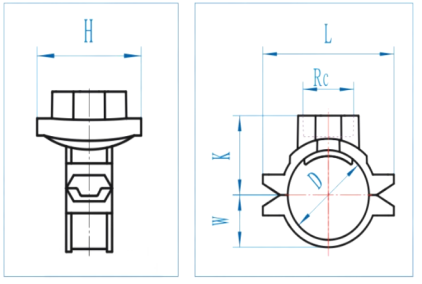

What is the difference between a mechanical tee and a grooved tee? This is a question that many laypeople often ask. The same is a tee fitting. The mechanical tee and the grooved tee are actually quite different. First, look at the following two pictures:

Judging from the pictures, the two grooved products are very different. The grooved mechanical tee has two more threads and nuts and rubber rings than the grooved tee. Below I will describe their specific uses separately.

● effect:

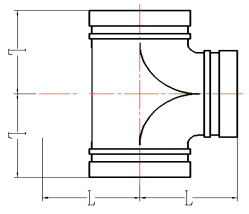

A tee has three openings, one inlet, and two outlets, or two inlets and one outlet. A tee is a pipe fitting applied to a pipeline system, with T-shaped and Y-shaped, with equal-diameter nozzles and different-diameter nozzles, used for the convergence of three identical or different pipelines. The main function of the tee is to change the direction of the fluid.

● Install:

Grooved tees should be installed in grooved piping systems. All three outlets of the grooved tee should be connected to the pipe by rigid or flexible couplings. See below:

Regarding the similarities and differences between rigid clamps and flexible clamps, you can click the link below for a more detailed introduction to the article:

⑴ Reasons to use a grooved mechanical tee:

To lead out a branch pipe with a different diameter, a mechanical tee is used in the construction process. A groove connection and a threaded connection are two types of connections. This type of connection is usually made for several reasons:

● Branch pipe must be installed somewhere on the main pipe.

Reducing tee can be used to lead a branch pipe out of an existing pipe of a fixed length (usually 6 meters), but the main pipe needs to be cut off.

● For the purpose of saving money.

The cost of a tee is greater than that of a mechanical tee. Under normal circumstances, mechanical tees are used when the diameter of the main pipe is 33, and U-shaped mechanical tees are usually used between 33 and 60. There are two ways to connect U-shaped mechanical tees: grooves or screws; they usually use 60 to 219 calibers, and they have an outer diameter of 21 to 33 inches (roughly 1/2" to 1"). The demand is not much different.

The threaded mechanical tee is a very special kind of grooved pipe fittings. It is similar to the grooved mechanical tee and is also widely used in grooved piping systems, but the branch pipe connection port of the threaded mechanical tee is connected by threads. The picture below shows the threaded mechanical tee.

Grooved Mechanical Tees

Pipe O.D(D × d) | Working Pressure | Dimensions | Bolt/Nut Size | |||||

mm/in | mm/in | PSI/Mpa | K (mm/in) | W (mm/in) | L (mm/in) | H(mm/in) | No. - Size (mm) | |

100 × 25 | 114.3 × 33.7 | 300PSI | 363PSI | 102 | 71 | 180 | 80 | M12×70 |

4 × 1 | 4.500 × 1.315 | 4.02 | 2.80 | 7.09 | 3.15 | |||

100 × 32 | 114.3 × 42.4 | 102 | 71 | 180 | 92 | M12×70 | ||

4 × 1¼ | 4.500 × 1.660 | 4.02 | 2.80 | 7.09 | 3.62 | |||

100 × 40 | 114.3 × 48.3 | 102 | 71 | 180 | 92 | M12×70 | ||

4 × 1½ | 4.500 × 1.900 | 4.02 | 2.80 | 7.09 | 3.62 | |||

100 × 50 | 114.3 × 60.3 | 102 | 71 | 180 | 107 | M12×70 | ||

4 × 2 | 4.500 × 2.375 | 4.02 | 2.80 | 7.09 | 4.21 | |||

100 × 65 | 114.3 × 76.1 | 102 | 71 | 180 | 114 | M12×70 | ||

4 × 2½ | 4.500 × 3.000 | 4.02 | 2.80 | 7.09 | 4.49 | |||

100 × 80 | 114.3 × 88.9 | 102 | 71 | 180 | 134 | M12×70 | ||

4 × 3 | 4.500 × 3.500 | 4.02 | 2.80 | 7.09 | 5.28 | |||

125 × 65 | 139.7 × 76.1 | 115 | 84 | 217 | 114 | M16×85 | ||

5 × 2½ | 5.500 × 3.000 | 4.53 | 3.31 | 8.54 | 4.49 | |||

125 × 80 | 139.7 × 88.9 | 115 | 84 | 217 | 134 | M16×85 | ||

5 × 3 | 5.500 × 3.500 | 4.53 | 3.31 | 8.54 | 5.28 | |||

150 × 65 | 159.0 × 76.1 | 125 | 93 | 239 | 114 | M16×95 | ||

6 × 2½ | 6.250 × 3.000 | 4.92 | 3.66 | 9.41 | 4.49 | |||

150 × 80 | 159.0 × 88.9 | 125 | 93 | 239 | 134 | M16×95 | ||

6 × 3 | 6.250 × 3.500 | 4.92 | 3.66 | 9.41 | 5.28 | |||

150 × 100 | 159.0 × 108.0 | 130 | 93 | 239 | 162 | M16×95 | ||

6 × 4 | 6.250 × 4.250 | 5.12 | 3.66 | 9.41 | 6.38 | |||

150 × 50 | 165.1 × 60.3 | 128 | 97 | 244 | 107 | M16×95 | ||

6 × 2 | 6.500 × 2.375 | 5.04 | 3.82 | 9.61 | 4.21 | |||

150 × 65 | 165.1 × 76.1 | 128 | 97 | 244 | 114 | M16×95 | ||

6 × 2½ | 6.500 × 3.000 | 5.04 | 3.82 | 9.61 | 4.49 | |||

150 × 80 | 165.1 × 88.9 | 128 | 97 | 244 | 134 | M16×95 | ||

6 × 3 | 6.500 × 3.500 | 5.04 | 3.82 | 9.61 | 5.28 | |||

150 × 100 | 165.1 × 114.3 | 133 | 97 | 244 | 162 | M16×95 | ||

6 × 4 | 6.500 × 4.500 | 5.24 | 3.82 | 9.61 | 6.38 | |||

200 × 50 | 219.1 × 60.3 | 156 | 126 | 307 | 107 | M16×100 | ||

8 × 2 | 8.625 × 2.375 | 6.14 | 4.96 | 12.09 | 4.21 | |||

200 × 65 | 219.1 × 76.1 | 156 | 126 | 307 | 114 | M16×100 | ||

8 × 2½ | 8.625 × 3.000 | 6.14 | 4.96 | 12.09 | 4.49 | |||

200 × 80 | 219.1 × 88.9 | 156 | 126 | 307 | 134 | M16×100 | ||

8 × 3 | 8.625 × 3.500 | 6.14 | 4.96 | 12.09 | 5.28 | |||

200 × 100 | 219.1 × 114.3 | 158 | 126 | 307 | 162 | M16×100 | ||

8 × 4 | 8.625 × 4.500 | 6.22 | 4.96 | 12.09 | 6.38 | |||

250 × 100 | 273.0× 114.3 | 187 | 152 | 384 | 162 | M20×110 | ||

10 × 4 | 10.750 × 4.500 | 7.36 | 5.98 | 15.12 | 6.38 | |||

Grooved Threaded Tees

0 | Pipe O.D(D × Rc) | Working Pressure | Dimensions | Bolt/Nut Size | ||||

mm/in | mm/in | PSI/Mpa | K (mm/in) | W (mm/in) | L (mm/in) | H (mm/in) | No. - Size (mm) | |

65 × 25 | 76.1 × 33.7 | 300PSI | 363PSI | 68 | 51 | 136 | 80 | M12×65 |

2½ × 1 | 3.000 × 1.315 | 2.68 | 2.01 | 5.35 | 3.15 | |||

65 × 32 | 76.1 × 42.4 | 70 | 51 | 136 | 92 | M12×65 | ||

2½ × 1¼ | 3.000 × 1.660 | 2.76 | 2.01 | 5.35 | 3.62 | |||

65 × 40 | 76.1 × 48.3 | 70 | 51 | 136 | 92 | M12×65 | ||

2½ × 1½ | 3.000 × 1.900 | 2.76 | 2.01 | 5.35 | 3.62 | |||

80 × 25 | 88.9 × 33.7 | 75 | 58 | 149 | 80 | M12×65 | ||

3 × 1 | 3.500 × 1.315 | 2.95 | 2.28 | 5.87 | 3.15 | |||

80 × 32 | 88.9 × 42.4 | 78 | 58 | 149 | 92 | M12×65 | ||

3 × 1¼ | 3.500 × 1.660 | 3.07 | 2.28 | 5.87 | 3.62 | |||

80 × 40 | 88.9 × 48.3 | 78 | 58 | 149 | 92 | M12×65 | ||

3 × 1½ | 3.500 × 1.900 | 3.07 | 2.28 | 5.87 | 3.62 | |||

80 × 50 | 88.9 × 60.3 | 82 | 58 | 149 | 107 | M12×65 | ||

3 × 2 | 3.500 × 2.375 | 3.23 | 2.28 | 5.87 | 4.21 | |||

100 × 25 | 108.0 × 33.7 | 87.5 | 68 | 174 | 80 | M12×70 | ||

4 × 1 | 4.250 × 1.315 | 3.44 | 2.68 | 6.85 | 3.15 | |||

100 × 32 | 108.0 × 42.4 | 90 | 68 | 174 | 92 | M12×70 | ||

4 × 1¼ | 4.250 × 1.660 | 3.54 | 2.68 | 6.85 | 3.62 | |||

100 × 40 | 108.0 × 48.3 | 90 | 68 | 174 | 92 | M12×70 | ||

4 × 1½ | 4.250 × 1.900 | 3.54 | 2.68 | 6.85 | 3.62 | |||

100 × 50 | 108.0 × 60.3 | 94 | 68 | 174 | 107 | M12×70 | ||

4 × 2 | 4.250 × 2.375 | 3.70 | 2.68 | 6.85 | 4.21 | |||

100 × 65 | 108.0 × 76.1 | 100 | 68 | 174 | 114 | M12×70 | ||

4 × 2½ | 4.250 × 3.000 | 3.94 | 2.68 | 6.85 | 4.49 | |||

100 × 25 | 114.3 × 33.7 | 90 | 71 | 180 | 80 | M12×70 | ||

4 × 1 | 4.500 × 1.315 | 3.54 | 2.80 | 7.09 | 3.15 | |||

100 × 32 | 114.3 × 42.4 | 92 | 71 | 180 | 92 | M12×70 | ||

4 × 1¼ | 4.500 × 1.660 | 3.62 | 2.80 | 7.09 | 3.62 | |||

100 × 40 | 114.3 × 48.3 | 92.5 | 71 | 180 | 92 | M12×70 | ||

4 × 1½ | 4.500 × 1.900 | 3.64 | 2.80 | 7.09 | 3.62 | |||

100 × 50 | 114.3 × 60.3 | 96 | 71 | 180 | 107 | M12×70 | ||

4 × 2 | 4.500 × 2.375 | 3.78 | 2.80 | 7.09 | 4.21 | |||

100 × 65 | 114.3 × 76.1 | 103 | 71 | 180 | 114 | M12×70 | ||

4 × 2½ | 4.500 × 3.000 | 4.06 | 2.80 | 7.09 | 4.49 | |||

100 × 80 | 114.3 × 88.9 | 104 | 71 | 180 | 134 | M12×70 | ||

4 × 3 | 4.500 × 3.500 | 4.09 | 2.80 | 7.09 | 5.28 | |||

125 × 65 | 133.0 × 76.1 | 112 | 80 | 210 | 114 | M16×85 | ||

5 × 2½ | 5.250 × 3.000 | 4.41 | 3.15 | 8.27 | 4.49 | |||

125 × 80 | 133.0 × 88.9 | 113 | 80 | 210 | 134 | M16×85 | ||

5 × 3 | 5.250 × 3.500 | 4.45 | 3.15 | 8.27 | 5.28 | |||

125 × 25 | 139.7 × 33.7 | 103 | 84 | 217 | 80 | M16×85 | ||

5 × 1 | 5.500 × 1.315 | 4.06 | 3.31 | 8.54 | 3.15 | |||

125 × 32 | 139.7 × 42.4 | 105 | 84 | 217 | 92 | M16×85 | ||

5 × 1¼ | 5.500 × 1.660 | 4.13 | 3.31 | 8.54 | 3.62 | |||

125 × 40 | 139.7 × 48.3 | 105 | 84 | 217 | 92 | M16×85 | ||

5 × 1½ | 5.500 × 1.900 | 4.13 | 3.31 | 8.54 | 3.62 | |||

125 × 50 | 139.7 × 60.3 | 109 | 84 | 217 | 107 | M16×85 | ||

5 × 2 | 5.500 × 2.375 | 4.29 | 3.31 | 8.54 | 4.21 | |||

125 × 65 | 139.7 × 76.1 | 116 | 84 | 217 | 114 | M16×85 | ||

5 × 2½ | 5.500 × 3.000 | 4.57 | 3.31 | 8.54 | 4.49 | |||

125 × 80 | 139.7 × 88.9 | 117 | 84 | 217 | 134 | M16×85 | ||

5 × 3 | 5.500 × 3.500 | 4.61 | 3.31 | 8.54 | 5.28 | |||

150 × 25 | 159.0 × 33.7 | 114 | 93 | 239 | 80 | M16×95 | ||

6 × 1 | 6.250 × 1.315 | 4.49 | 3.66 | 9.41 | 3.15 | |||

150 × 32 | 159.0 × 42.4 | 116 | 93 | 239 | 92 | M16×95 | ||

6 × 1¼ | 6.250 × 1.660 | 4.57 | 3.66 | 9.41 | 3.62 | |||

150 × 40 | 159.0 × 48.3 | 116 | 93 | 239 | 92 | M16×95 | ||

6 × 1½ | 6.250 × 1.900 | 4.57 | 3.66 | 9.41 | 3.62 | |||

150 × 50 | 159.0 × 60.3 | 119 | 93 | 239 | 107 | M16×95 | ||

6 × 2 | 6.250 × 2.375 | 4.69 | 3.66 | 9.41 | 4.21 | |||

150 × 65 | 159.0 × 76.1 | 124 | 93 | 239 | 114 | M16×95 | ||

6 × 2½ | 6.250 × 3.000 | 4.88 | 3.66 | 9.41 | 4.49 | |||

150 × 80 | 159.0 × 88.9 | 125 | 93 | 239 | 134 | M16×95 | ||

6 × 3 | 6.250 × 3.500 | 4.92 | 3.66 | 9.41 | 5.28 | |||

150 × 25 | 165.1 × 33.7 | 117 | 97 | 244 | 80 | M16×95 | ||

6 × 1 | 6.500 × 1.315 | 4.61 | 3.82 | 9.61 | 3.15 | |||

150 × 32 | 165.1 × 42.4 | 118 | 97 | 244 | 92 | M16×95 | ||

6 × 1¼ | 6.500 × 1.660 | 4.65 | 3.82 | 9.61 | 3.62 | |||

150 × 40 | 165.1 × 48.3 | 120 | 97 | 244 | 92 | M16×95 | ||

6 × 1½ | 6.500 × 1.900 | 4.72 | 3.82 | 9.61 | 3.62 | |||

150 × 50 | 165.1 × 60.3 | 122 | 97 | 244 | 107 | M16×95 | ||

6 × 2 | 6.500 × 2.375 | 4.80 | 3.82 | 9.61 | 4.21 | |||

150 × 65 | 165.1 × 76.1 | 127 | 97 | 244 | 114 | M16×95 | ||

6 × 2½ | 6.500 × 3.000 | 5.00 | 3.82 | 9.61 | 4.49 | |||

150 × 80 | 165.1 × 88.9 | 128 | 97 | 244 | 134 | M16×95 | ||

6 × 3 | 6.500 × 3.500 | 5.04 | 3.82 | 9.61 | 5.28 | |||

150 × 100 | 165.1 × 114.3 | 132 | 97 | 244 | 162 | M16×95 | ||

6 × 4 | 6.500 × 4.500 | 5.20 | 3.82 | 9.61 | 6.38 | |||

200 × 25 | 219.1 × 33.7 | 143 | 126 | 307 | 80 | M16×100 | ||

8 × 1 | 8.625 × 1.315 | 5.63 | 4.96 | 12.09 | 3.15 | |||

200 × 32 | 219.1 × 42.4 | 145 | 126 | 307 | 92 | M16×100 | ||

8 × 1¼ | 8.625 × 1.660 | 5.71 | 4.96 | 12.09 | 3.62 | |||

200 × 40 | 219.1 × 48.3 | 145 | 126 | 307 | 92 | M16×100 | ||

8 × 1½ | 8.625 × 1.900 | 5.71 | 4.96 | 12.09 | 3.62 | |||

200 × 50 | 219.1 × 60.3 | 149 | 126 | 307 | 107 | M16×100 | ||

8 × 2 | 8.625 × 2.375 | 5.87 | 4.96 | 12.09 | 4.21 | |||

200 × 65 | 219.1 × 76.1 | 155 | 126 | 307 | 114 | M16×100 | ||

8 × 2½ | 8.625 × 3.000 | 6.10 | 4.96 | 12.09 | 4.49 | |||

200 × 80 | 219.1 × 88.9 | 158 | 126 | 307 | 134 | M16×100 | ||

8 × 3 | 8.625 × 3.500 | 6.22 | 4.96 | 12.09 | 5.28 | |||

250 × 25 | 273.0 × 33.7 | 175 | 152 | 384 | 80 | M20×110 | ||

10 × 1 | 10.750 × 1.315 | 6.89 | 5.98 | 15.12 | 3.15 | |||

250 × 50 | 273.0 × 60.3 | 179 | 152 | 384 | 107 | M20×110 | ||

10 × 2 | 10.750 × 2.375 | 7.05 | 5.98 | 15.12 | 4.21 | |||

Grooved Tees

Nominal Size | Pipe O.D | Working Pressure | Dimensions | |

mm/in | mm/in | PSI/Mpa | L (mm/in) | |

50 | 60.3 | 300PSI | 363PSI | 68.5 |

2 | 2.374 | 2.697 | ||

65 | 76.1 | 74 | ||

2½ | 2.996 | 2.913 | ||

80 | 88.9 | 84 | ||

3 | 3.500 | 3.307 | ||

100 | 108.0 | 100 | ||

4 | 4.252 | 3.937 | ||

100 | 114.3 | 100 | ||

4 | 4.500 | 3.937 | ||

125 | 133.0 | 122 | ||

5 | 5.236 | 4.803 | ||

125 | 139.7 | 122 | ||

5 | 5.500 | 4.803 | ||

150 | 159.0 | 138 | ||

6 | 6.260 | 5.433 | ||

150 | 165.1 | 138 | ||

6 | 6.500 | 5.433 | ||

200 | 219.1 | 171 | ||

8 | 8.626 | 6.732 | ||

250 | 273.0 | 212 | ||

10 | 10.748 | 8.346 | ||

300 | 323.9 | 242 | ||

12 | 12.752 | 9.528 | ||

250 | 273.0 | 225PSI | 363PSI | 212 |

10 | 10.748 | 8.346 | ||

300 | 323.9 | 242 | ||

12 | 12.752 | 9.528 | ||

If you are interested in grooved pipe fittings, please click the link below to enter the official website of Jianzhi Group to see more about grooved pipe fittings.

https://www.malleableiron-pipefitting.com/

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 18698027872

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania

Service email: info.ro@jianzhi-fitting.com

Sales email: market.ro@jianzhi-fitting.com

Tel: +40(755)011 849