Mar. 23, 2023

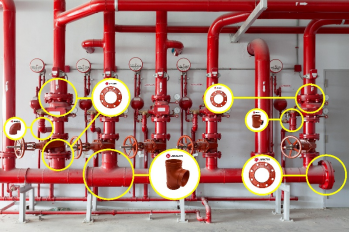

There are many types of grooved pipe fittings, including rigid couplings and flexible couplings for pipes, open-hole mechanical tees, crosses and grooved tees, crosses, single-piece flanges and grooved flanges, etc., which have similar functions, but the usage occasions are different. Before installation, you should have an in-depth understanding of the performance and service conditions of various couplings and accessories, so that you can choose them correctly. The most important of these is to distinguish the difference between a flexible joint and a flexible joint.

In engineering construction, due to insufficient technical disclosure and quality monitoring, workers often do not distinguish between rigid couplings and flexible couplings, and use them at will, which brings hidden dangers to the reliable operation and normal maintenance of the entire pipeline system.

For example: in the domestic hot water system, the temperature difference between the system operating temperature and the pipe installation temperature can reach 60°C, and the steel pipe is 6m long, and the resulting thermal expansion stress will reach 1200kg/mm2. If the pipe is rigidly connected, it will cause deformation of the bracket and cause damage to the pipe system. Therefore, the butt joint fittings should be distinguished and selected reasonably.

The following typical situations reveal the difference between rigid and flexible couplings:

1. Domestic hot water pipes, air-conditioning water pipes, and open-air pipes, in order to effectively compensate for the pipe displacement caused by thermal expansion and contraction, the above three types must use flexible couplings. If the displacement of the telescopic section exceeds the total compensation amount of the flexible couplings, should also consider installing metal expansion couplings.

2. Pipes with little change in temperature difference, such as indoor fire-fighting pipes, can use a large number of rigid couplings. However, a certain number of flexible couplings should be installed in the middle section of the long straight pipeline to compensate for a small amount of thermal expansion of the long straight pipeline section to ensure that the entire pipeline system is in a safe operating state.

3. For bent pipes and zigzag pipes with temperature compensation function, flexible couplings shall be installed on the pipe sections where angular displacement occurs.

4. It is recommended to use flexible couplings for pump room pipelines to reduce noise and weaken vibration transmission.

5. Flexible couplings should be used for buried pipelines, which can effectively deal with local deformation of the pipeline system caused by uneven settlement.

6. Flexible pipe couplings must be used for the connection of small arc pipes. It can be assembled according to the straight pipe first, and then bend the pipe to make it reach the predetermined corner. But under no circumstances should the angle of rotation exceed the value specified in the instructions for grooved pipe fittings.

You can click the link below to watch more exciting videos about grooved pipe fittings.

https://www.youtube.com/channel/UC3meidzbmzv6n5neIX-symw

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 18698027872

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania

Service email: info.ro@jianzhi-fitting.com

Sales email: market.ro@jianzhi-fitting.com

Tel: +40(755)011 849