May. 18, 2023

1) Fire Hydrant System: For overhead pipes, hot-dip galvanized steel pipes can be used when the system operating pressure is ≤1.20 MPa. When the system operating pressure is >1.20 MPa, hot-dip galvanized thickened steel pipes or hot-dip galvanized seamless steel pipes should be used. When the system operating pressure is >1.60 MPa, hot-dip galvanized seamless steel pipes should be used.

2) Elevated Fire Water Tank: When the water tank is installed outdoors on the roof, measures such as locks for manholes and protective enclosures for valves of inlet and outlet pipes should be taken.

3) Butterfly valves installed on the inlet and outlet pipes of fire pumps should have a self-locking device.

4) Automatic sprinkler system: Grooved fittings should be used for the connection between the main water supply pipe (riser) and the distribution pipes (horizontal pipes), and mechanical tees should not be used.

1) Sprinkler Heads:

Sprinkler heads should be installed centrally (in coordination with the layout of decorative ceilings), aligning with lights, smoke detectors, etc., to avoid conflicts.

Sealing performance test for closed-type sprinkler heads: 1% of each batch, not less than 5 units, should be randomly selected for a pressure test at 3 MPa for a minimum duration of 3 minutes. If there are two or more failed units, the entire batch of sprinkler heads should not be used. If there is one failed unit, an additional 2% should be randomly tested, not less than 10 units. If there are still failed units, the batch should not be used.

The distance between the deflector of a standard sprinkler head and the ceiling should be 75-150 mm. For sidewall-type standard sprinkler heads, the distances from the deflector to the ceiling and the wall should be 100-150 mm and 50-100 mm, respectively.

Before installation, establish a reference line and elevation line for the finished suspended ceiling. After adjusting the suspension grids, measure the length of the short pipe for each sprinkler head and install them to prevent them from being too long or too short. Sprinkler arms (single or double) should be installed uniformly in either a vertical or horizontal orientation.

Decorative coatings should not be applied to the decorative covers of sprinkler heads or concealed sprinkler heads. Decorative covers or caps should be closely attached to the suspended ceiling.

The deflector shield for sprinkler heads should be square or circular and made of metal, with a planar area not less than 0.12 m².

The sprinkler head, light, smoke detector, and air outlet are in a straight line.

The sprinkler head is not installed in the center

The installation length of the sprinkler head is too short

The installation length of the sprinkler head is too long

The sprinkler head cover does not fit properly with the ceiling

2) Alarm Valve:

Before installation, conduct a leakage test with a test pressure of twice the rated working pressure, maintaining the pressure for a minimum of 5 minutes.

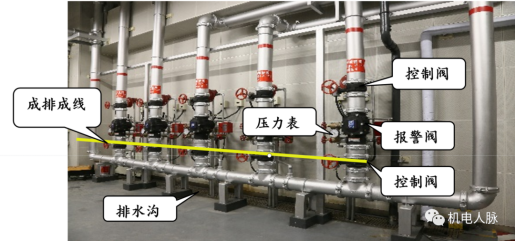

The installation height should be 1.2m above the indoor floor level. The distance from the valve to the side walls should be not less than 0.5m, and the distance from the front wall should be not less than 1.2m. The distance between protruding parts of alarm valve assemblies should be not less than 0.5m. Signal valves should be used for the control valves of the alarm valve inlet and outlet, and if not used, a lock should be provided for the control valve.

Installation of the alarm valve assembly

3) Hydraulic Alarm Bell: It should be installed near locations where personnel are on duty or on the exterior walls of public corridors. The diameter of the pipeline connecting to the alarm valve should be 20mm, and its length should not exceed 20m.

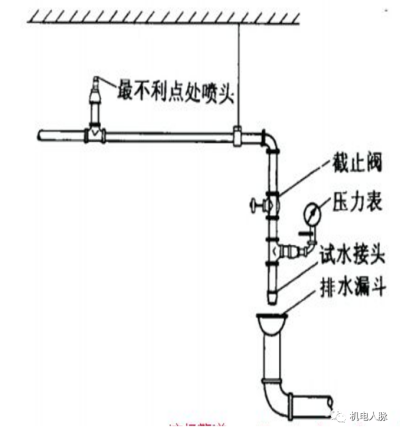

4) End-of-line test devices: They should be clearly marked and positioned at a height of 1.5m above the ground level, taking measures to prevent interference or misuse.

Hydraulic alarm bell installed in public corridor

Hydraulic alarm bell installed in the machine room

Installation of the end-of-line test device

1) The fixed interface of fire hydrants should undergo a sealing performance test to ensure no leakage or damage. The test should include a random sampling of 1% of the batch, not less than 5 units, pressurized to 1.6 MPa and maintained for 2 minutes. If two or more units are found to be non-compliant, the batch of fire hydrants should not be used. If only one unit is non-compliant, an additional 2% should be randomly tested, but not less than 10 units, and undergo a retest of the sealing performance. If there are still non-compliant units, they should not be used.

2) The distance between the fire hydrant center and the side of the box should be 140mm, and the distance from the inner surface of the back of the box should be 100mm. The height of the hydrant outlet from the ground should be 1.1m.

3) The installation of indoor fire hydrant cabinets should be neat and secure, with a permissible deviation of ±3mm for verticality of the cabinet. The cabinet door should open to an angle not less than 120°. If decorative materials such as stone are used for the fire hydrant cabinet door, it should open flexibly (opening tension ≤ 50N).

4) Individual fire hydrants should not be installed on the side of the fire hydrant cabinet door hinge.

5) After the installation of the fire hydrant cabinet, any excess holes and gaps should be sealed.

6) Indoor fire hydrant system testing: Conduct a test discharge on a rooftop test hydrant and two hydrants on the first floor to ensure compliance with design requirements. Measure the flow rate and pressure of the rooftop hydrant, and check the ability of the two hydrants on the first floor to simultaneously deliver two solid water columns to the farthest point they should reach.

Fire hydrant installed on the side of the door opening

Fire hydrant installed on the side of the door hinge

There are gaps in the fire hydrant box openings

Seal the gaps in the fire hydrant box openings

The direction of opening the box affects the operation

The fire riser affects the opening of the box

The elevator door affects the opening of the box

1) Wall-mounted Fire Pump Connectors: When there are no specific design requirements, the installation height should be 0.7m. They should be installed at a distance of not less than 2m from doors, windows, holes, or openings on the wall, and should not be installed below glass curtain walls.

2) The distance between the inlet of an underground Fire Pump Connector and the bottom surface of the well cover should be no greater than 0.4m and not less than the radius of the well cover.

Above-ground fire pump coupling

Various types of fire pump couplings

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 18698027872

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania

Service email: info.ro@jianzhi-fitting.com

Sales email: market.ro@jianzhi-fitting.com

Tel: +40(755)011 849