Grooved Flexible Pipe Couplings are a type of coupling that allows for some movement at the joint. They are designed to transmit torque while accommodating radial, axial, and angular misalignment. These couplings are ideal for use in applications with a certain degree of flexibility, such as pipelines in mining, irrigation, and compressed air systems. Flexible couplings for pipes can accommodate angular misalignments of up to a few degrees and some parallel misalignments, making them suitable for use in machinery and pipelines, process pipelines, mining and oilfield pipelines, and more. They are particularly useful when up to 5% deflection is required, as they can help reduce the risk of damage or failure due to misalignment.

Product Description

Available sizes: 1 – 12 inch

Working pressure: 300 PSI FM approved / UL certified

Coating: red painted/galvanized / epoxy blue / grey

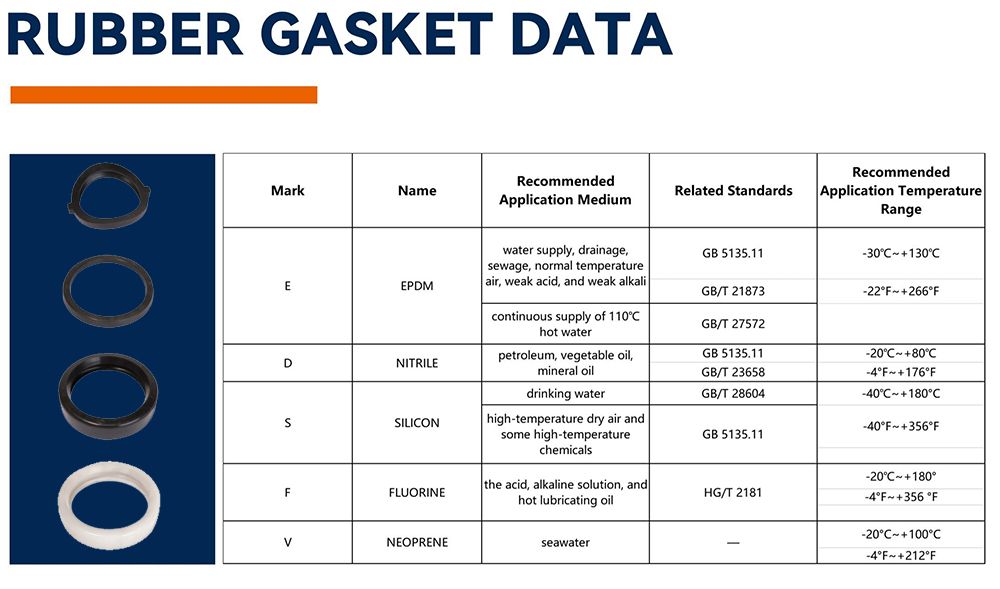

Gasket: EPDM / NITRILE / SILICON

The pipe coupling or coupler plays an important role in connecting pipe sections and is used to stop leaks from broken or damaged couplings while maintaining the integrity of the pipe during the process. It is a very proper fitting for the pipeline and plumbing industry. Most pipeline installations require multiple sections of pipe to be joined together or cut to facilitate changes of direction and crossing obstacles. A pipe joint is a concise piece of pipe or tubing. It has a socket or internal thread at one or both ends. A pipe coupling allows two pipes or tubes of the same or different sizes to be joined together to form a long pipe.

Flexible couplings are designed to transmit torque while permitting some radial, axial and angular misalignment. They can accommodate angular misalignment up to a few degrees and some parallel misalignment. The flexible couplings allow some angular misalignment and axial movement, which means that they can be used to create smooth bends and absorb thermal expansion a contraction in the piping system. In some cases, traditional expansion joints, loops, and other expansion devices may even be completely excluded from the system with the use of flexible couplings. When assembling stretched rubber gasket that is slightly smaller than the pipe diameter of the two pipe ends and creates the first seal. The coupling halves are then placed around the gasket which adapts to them. The coupling halves are bolted together to further improve the sealing. When the piping system is pressurized, a ”pressure reserve” is created due to the profile of the gasket. The sealing lips are pressed at the increasing pressure harder down against the gasket seating surface which creates the third seal and makes the connection completely leak-proof and airtight. The working temperature of the gaskets is -34°C to +110°C.

Overview of Pipe Coupling and Pipe Coupling Types

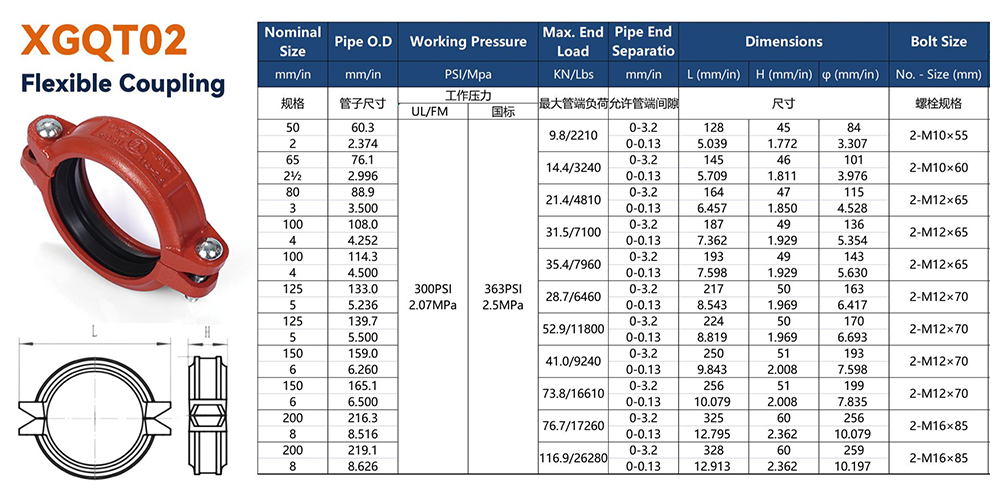

Product Dimensions

| Nominal Size | Pipe O.D | Working Pressure | |

| mm/in | mm/in | PSI/Mpa | |

| UL/FM | Standard | ||

| 50mm | 60.3 | 300PSI 2.07MPa UL/FM | 363PSI 2.5MPa |

| 2inch | 2.374 inch | ||

| 65mm | 76.1 | ||

| 2½inch | 2.996inch | ||

| 80mm | 88.9 | ||

| 3inch | 3.500inch | ||

| 100mm | 108.0 | ||

| 4inch | 4.252 inch | ||

| 100mm | 114.3 | ||

| 4inch | 4.500inch | ||

| 125mm | 133.0 | ||

| 5inch | 5.236 inch | ||

| 125mm | 139.7 | ||

| 5inch | 5.500inch | ||

| 150mm | 159.0 | ||

| 6inch | 6.260 inch | ||

| 150mm | 165.1 | ||

| 6inch | 6.500 inch | ||

| 200mm | 216.3 | ||

| 8inch | 8.516inch | ||

| 200mm | 219.1 | ||

| 8inch | 8.626 inch | ||

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 18698027872

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania

Service email: info.ro@jianzhi-fitting.com

Sales email: market.ro@jianzhi-fitting.com

Tel: +40(755)011 849