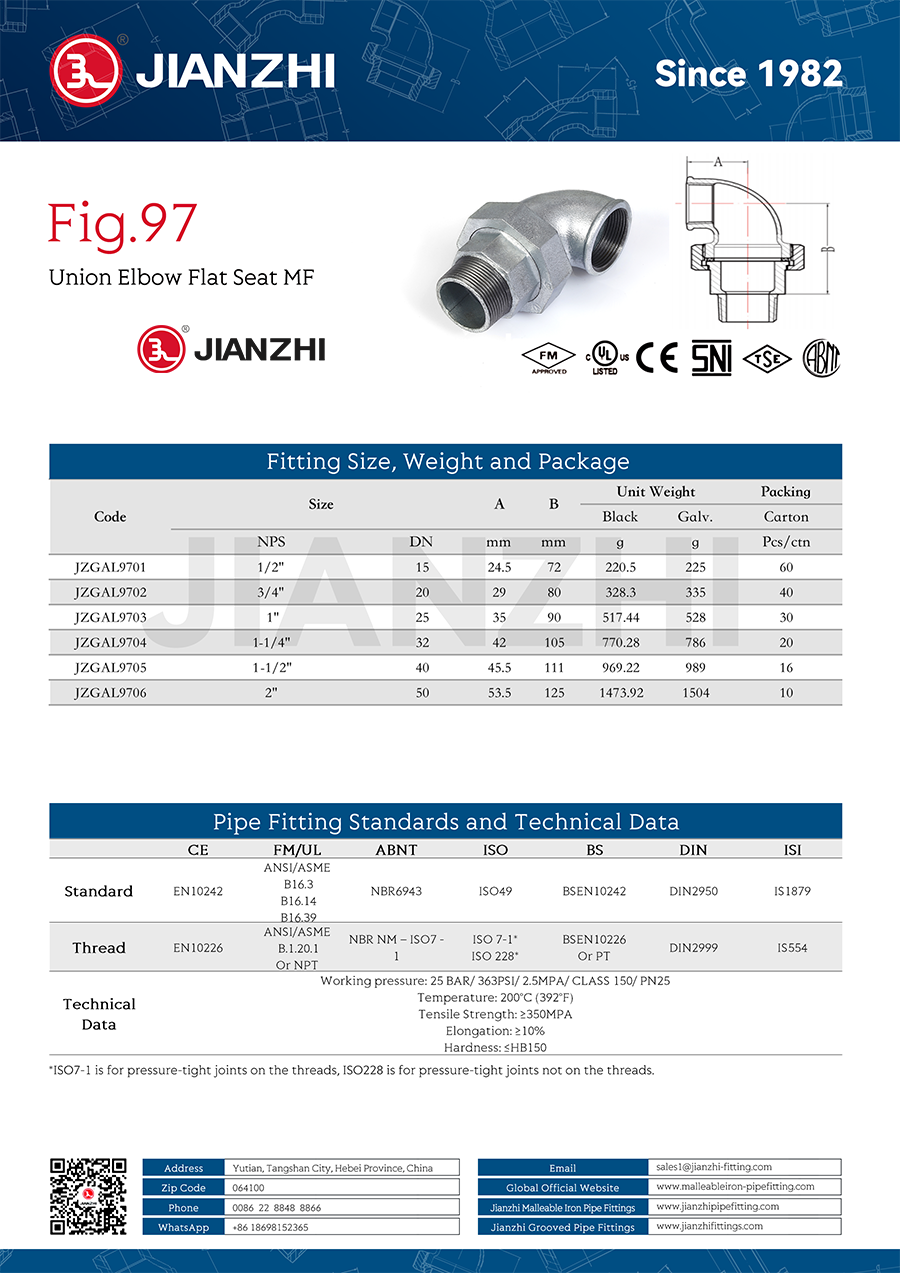

Size: 1/2''-2''(DN15-DN50)

Standard: EN10242 / ANSI / ASME B16.3 / DIN2950 / IS0 49 / NBR6943 / IS1879 / BS EN10242

Threaded Standard: EN10226 / ASME B.1.20.1 / DIN2999 / ISO7-1 / ISO228 / IS554 / BS EN10226

Work Pressures: PN25 / 2.5Mpa / 363PSI /CLASS 150 / 25Bar

UL Listed /FM Approved /CE /ABNT /TSE /SNI /ISI

Product Description

Maximum Pressure: 25 BAR (363PSI) (2.5MPA) CLASS 150

Maximum Temperature: 200°C (392°F)

Tensile Strength: 350MPA

Hardness: HB150 (Brinell)

Elongation Rate: 10%

Suitable Applications: Water, Oil, Gas, Petro-Chemical

Material: Malleable Iron

Galvanized pipe fittings refer to the treatment of galvanized pipe fittings. The base of the pipe and molten bath have complex physical and chemical reactions, forming a zinc ferroalloy layer with a close corrosion-resistant structure.

The alloy layer is integrated with a pure zinc layer and pipe base. Therefore, it has strong corrosion resistance. The main purpose of galvanizing is to enhance the corrosion resistance of pipe fittings. Hot-dip galvanized pipe fittings are mainly used for conveying gas, heating, and other pipeline projects. If the steel pipe body needs to be galvanized anti-corrosion treatment, the corresponding connecting pipe fittings should also be galvanized.

The main production process of hot dip galvanized pipe fittings is as follows: Degreasing → Rinsing → Pickling → Cleaning → Fluxing→ Hot air drying → Hot-dipped galvanizing → Cooling →Passivation and Rinsing.

Difference between hot dipped galvanized pipe fittings and electro galvanized pipe fittings:

Hot dipped galvanized pipe fittings:thick zinc layer, uniform zinc layer on the inner and outer walls, long service life.

Electro galvanized pipe fittings:thin zinc layer, smooth and beautiful surface, lower cost, but inner surface zinc layer is too thin.

Product Dimensions

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 18698027872

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania

Service email: info.ro@jianzhi-fitting.com

Sales email: market.ro@jianzhi-fitting.com

Tel: +40(755)011 849