Size: 1/8''-6''(DN6-DN150)

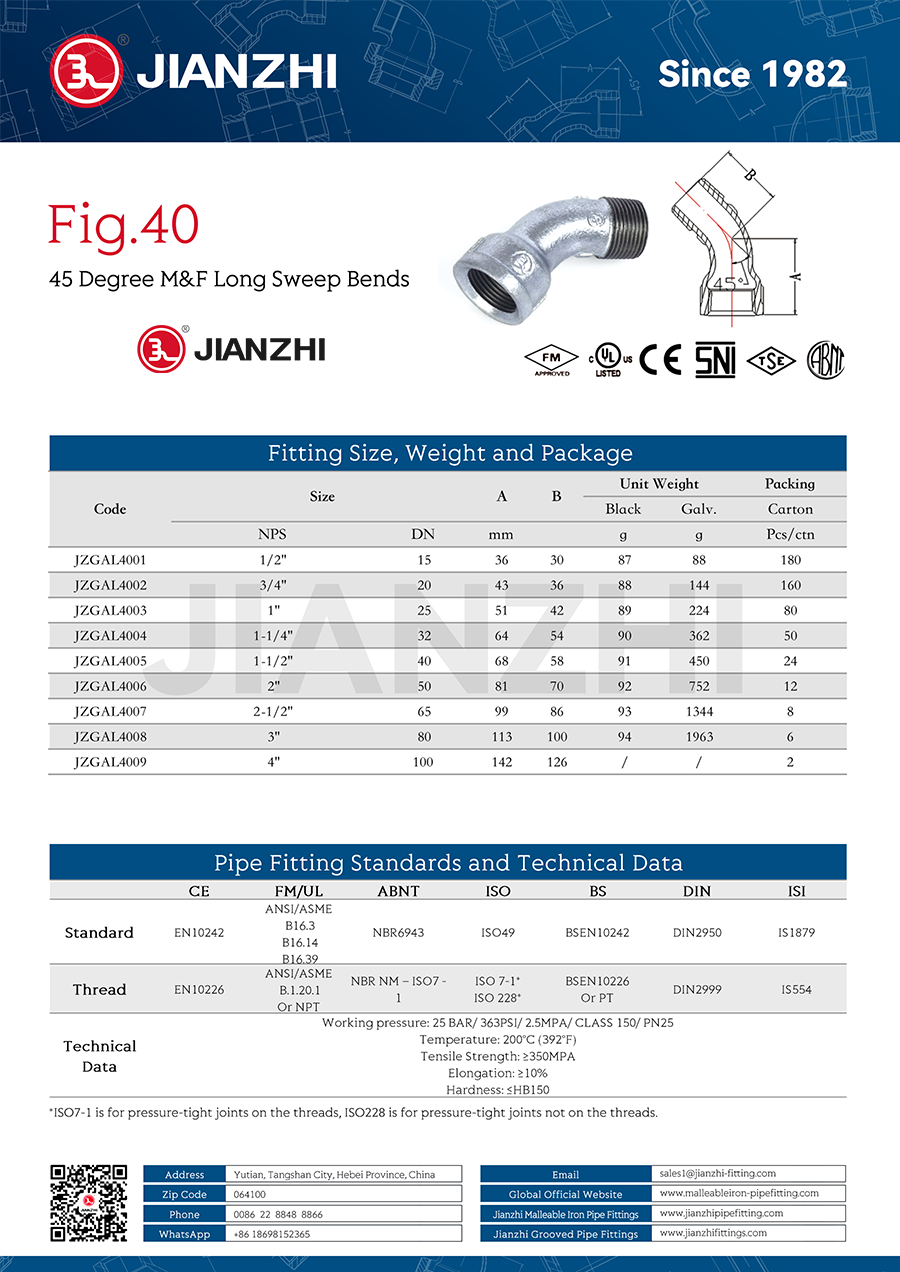

Standard: EN10242 / ANSI / ASME B16.3 / DIN2950 / IS0 49 / NBR6943 / IS1879 / BS EN10242

Threaded Standard: EN10226 / ASME B.1.20.1 / DIN2999 / ISO7-1 / ISO228 / IS554 / BS EN10226

Work Pressures: PN25 / 2.5Mpa / 363PSI /CLASS 150 / 25Bar

UL Listed /FM Approved /CE /ABNT /TSE /SNI /ISI

Product Description

Maximum Pressure: 25 BAR (363PSI) (2.5MPA) CLASS 150

Maximum Temperature: 200°C (392°F)

Tensile Strength: 350MPA

Hardness: HB150 (Brinell)

Elongation Rate: 10%

Suitable Applications: Water, Oil, Gas, Petro-Chemical

Material: Malleable Iron

45° bend pipe fittings. It can be divided into male thread bend, male and female thread bend. According to the surface treatment method, it can be divided into hot-tinned moon bend and black product moon bend. The size is from 1/2" to 4". Working pressure 2.5mpa.

45°Hot-dip galvanized bend, the surface is treated by hot-dip galvanizing process. The thickness of the zinc layer is more than 65um, which has good corrosion resistance. Usually used in oil and gas systems, gas systems, water resources systems, etc.

How we bend the elbow

Here are the general steps involved in bending a 45 degree pipe elbow:

Material Selection: Metal pipe elbows are typically made from materials such as stainless steel, carbon steel, or aluminum. The choice of material depends on the intended application and the required strength, corrosion resistance, and other properties.

Preparation: The pipe is inspected for any defects or imperfections that could affect the bending process. It may be cut to the desired length if needed.

Cold Bending: For small-diameter pipes and thinner materials, cold bending is commonly used. In this method, the pipe is placed in a bending machine or jig with the desired bending radius. Force is applied gradually, and the pipe is slowly bent to the desired angle. This process is often carried out using hydraulic or mechanical equipment.

Hot Bending: Hot bending is typically employed for larger-diameter and thicker-walled pipes that are not easily bent through cold forming. The pipe is heated to an elevated temperature, usually using an induction heating system or a furnace. Once the desired temperature is reached, the pipe is carefully shaped using hydraulic equipment or other specialized tools. Hot bending allows for greater flexibility and reduces the risk of pipe cracking or distortion.

Quality Control: After the bending process, the pipe elbow is inspected for dimensional accuracy, wall thickness consistency, and any defects or imperfections. Non-destructive testing methods such as visual inspection, ultrasonic testing, or radiography may be used to ensure the integrity of the bend.

Product Dimensions

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 15822792427

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania