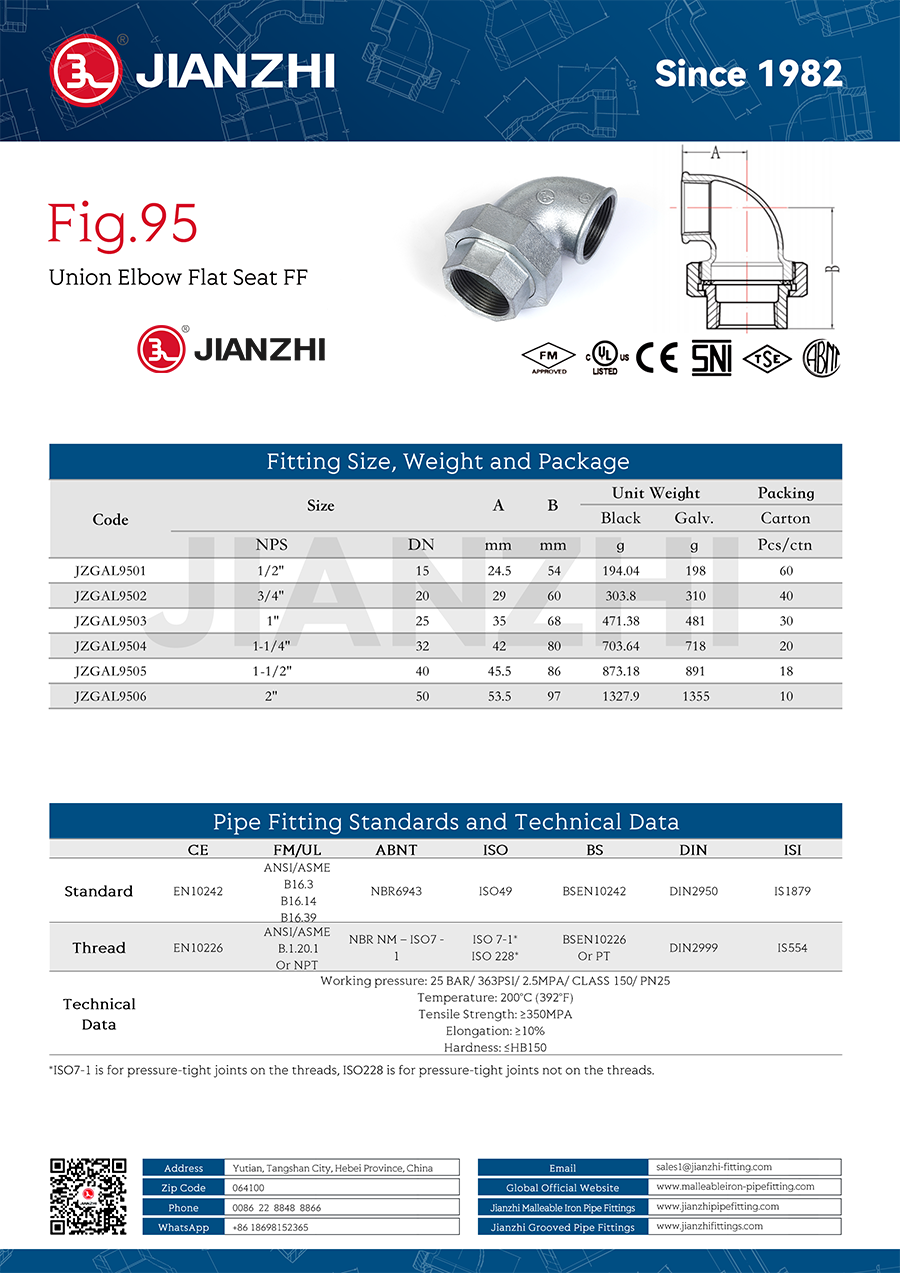

Size: 1/2''-2''(DN15-DN50)

Standard: EN10242 / ANSI / ASME B16.3 / DIN2950 / IS0 49 / NBR6943 / IS1879 / BS EN10242

Threaded Standard: EN10226 / ASME B.1.20.1 / DIN2999 / ISO7-1 / ISO228 / IS554 / BS EN10226

Work Pressures: PN25 / 2.5Mpa / 363PSI /CLASS 150 / 25Bar

UL Listed /FM Approved /CE /ABNT /TSE /SNI /ISI

Product Description

Maximum Pressure: 25 BAR (363PSI) (2.5MPA) CLASS 150

Maximum Temperature: 200°C (392°F)

Tensile Strength: 350MPA

Hardness: HB150 (Brinell)

Elongation Rate: 10%

Suitable Applications: Water, Oil, Gas, Petro-Chemical

Material: Malleable Iron

JIANZHI Group is a manufacturer of malleable steel pipe fittings with the most complete types and specifications.

Products are mainly used in water systems, petrochemical systems, gas systems, plumbing systems, among which our plastic-lined pipe fittings can be used in drinking water systems.

7 Key Advantages:

1. The mechanical properties of the materials for the construction and support pipe fittings are the highest

The malleable cast iron of KTH330-08 grade is used, the tensile strength is 10% higher than the national standard, the elongation is 33% higher than the national standard, and the branch pipe parts are 100% higher than the standard.

2. The appearance quality of the supporting pipe fittings is the best

The original sand is all primary water wash sand, and the most advanced automatic sand mixing system and advanced testing instruments are introduced to monitor at any time.

3. The accuracy of pipe thread is stricter than that of national standard

The national standard stipulates that the minimum length of 1” taper pipe internal thread shall not be less than 11.6mm (about 5 pipe threads) when the tool withdrawing structure is adopted; the minimum length of external thread shall not be less than 14.5mm (about 6.3 threads). In order to ensure the accuracy of the base plane position, we always control the base plane of the taper pipe thread in the best position during processing. The thread precision of the base surface dimension of the building and supporting pipe fittings is higher than that of the national standard. The national standard is ± 1/4 thread, and the building and supporting pipe fittings are within ±1 thread.

4. The control of the angle between the pipe thread axis is the most strict

According to the national standard, the deviation of pipe thread angle is not more than ± 0.5 ° and the construction pipe fittings are controlled within ± 0.3 ° which is 40% stricter than the national standard.

5. The airtightness of the supporting pipe fittings is the best

The inside of the pipe fittings shall be able to bear the normal temperature water pressure of no less than 2MPa or the air pressure of 0.5MPa. In order to ensure that the product is 100% qualified, we increase the air test pressure to more than 0.6MPa, which is more than 20% higher than the national standard.

6. The inspection cost of the construction and support pipe fittings is the highest

The company invented the "Chain Type Quality Management Achievement" and won the "First prize of enterprise management modernization innovation achievement" of the Ministry of Agriculture.

7. The installation cost of the construction and support pipe fittings is the lowest

Because Jianzhi fittings have many advantages, they can show outstanding advantages in the process of installation, and can greatly speed up the installation speed and reduce the installation cost.

Product Dimensions

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 18698027872

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania

Service email: info.ro@jianzhi-fitting.com

Sales email: market.ro@jianzhi-fitting.com

Tel: +40(755)011 849